Front Brake – What Front Brake? (Part 1)

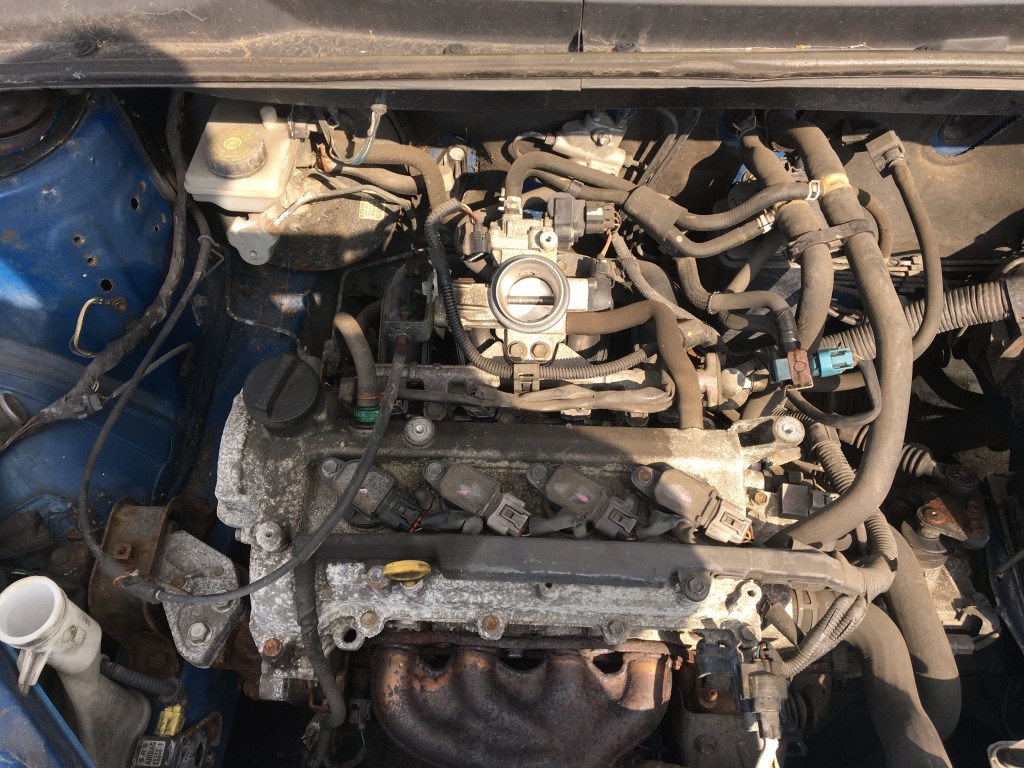

Motorcycling is in my blood [ RIP Dad – A Truly Great Father ] and because of motorcycles I’ve literally spilled many pints of blood [ Conscious Throughout ] My Dad passed the DNA and the bug to me in 1976 aged 15. My younger brother then aged 10 also caught the bug and eventually carried on the motorcycling tradition for far longer than myself. I rode on and off from age 15 to 40, all weathers, commuting on various ‘hack bikes’ while pampering and saving the main bike for dry (mainly) runs out for the sheer joy of riding. My brother recently bought a new 2023 Triumph 765 Street Triple R, a two wheeled sculpture if ever there was such a thing. The Street Triple was to join his stable of bikes alongside his classic Triumph Daytona 1200, and another classic, the Honda CB250 RSA you see below. The little Honda was his ‘hack bike’ back in the day, not used since 2010 and carefully stored, dry and covered in our Dad’s old garage. That garage is a shrine to our dear father, not really disturbed since his sad passing in 2016.

So the Street Triple needed room, the garage needs sorting but both my brother and I are dreading the day we have to disturb our Dad’s workshop and birthplace to so much of his woodwork creativity, and so many precious memories. The motorcycling bug never dies, although I myself have not ridden for over 20 years, the pull has always been there and watching the wonderful Allen Millyard‘s YouTube channel has fed my interest in the mean time, and when my brother suggested I take custody of his little classic Honda and get her back on the road I jumped at the chance!

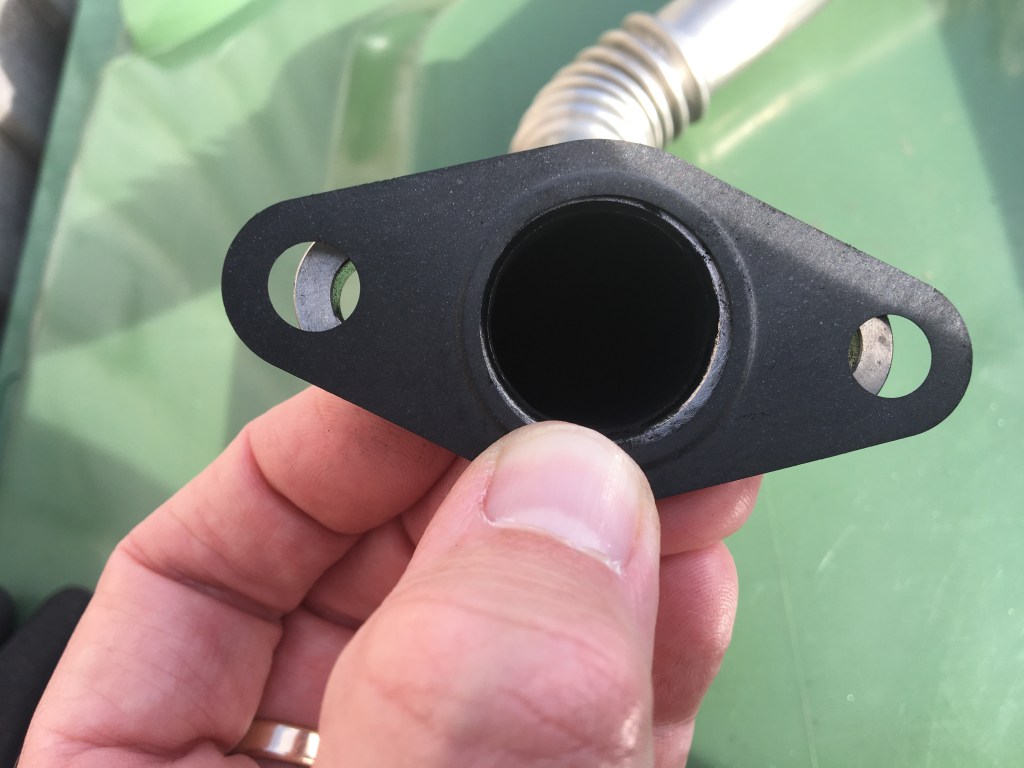

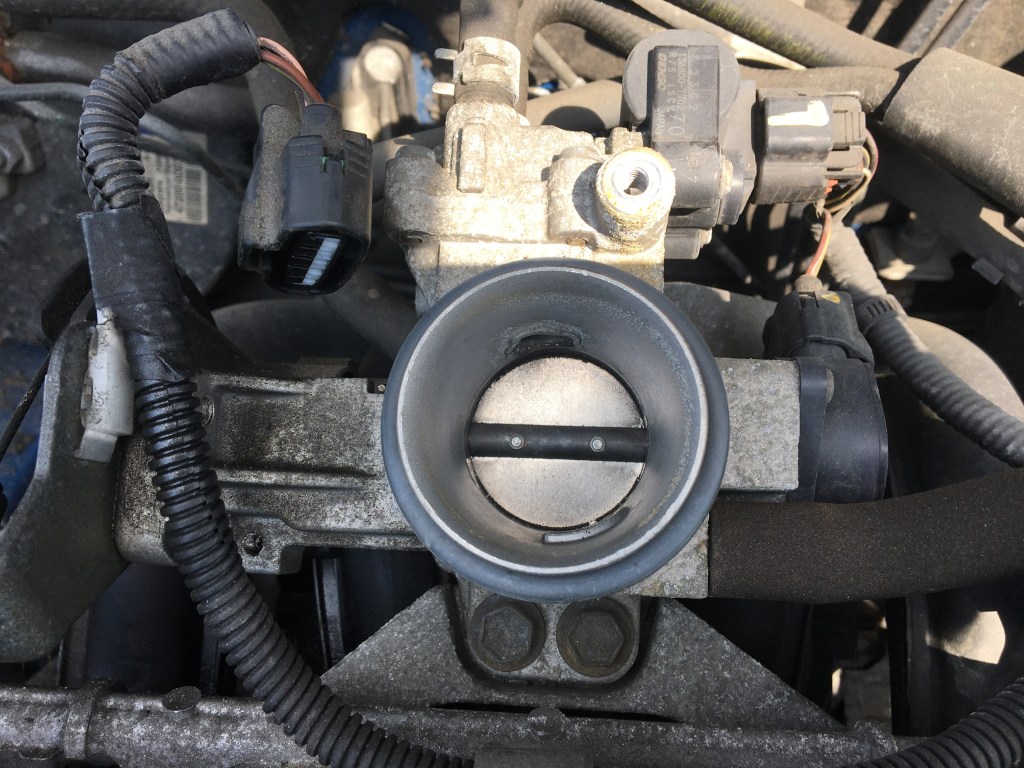

What follows is a pictorial account with description of the 1st phase of that restoration – The missing Front Brake …

So. I made my first rusty mechanic’s mistake here! I proceeded to fill the reservoir, and bleed the system via the brake caliper bleed nipple/drain tube etc. All Good. But it wasn’t! something was wrong and it soon became apparent that the calliper/piston/sliding half was seized! Stupid oversight, I should have stripped & inspected the brake calliper on a 40 year old bike that hadn’t been ridden since 2011!

Why ‘Zen’?

There’s a stand out section for me in the book Zen and the Art of Motorcycle Maintenance, and it is the part where the author describes making, or proposing to make makeshift ‘shims’ for his friends John and Sylvia Sutherland’s new and exclusively dealer serviced BMW motorcycle. Pirsig tries to explain how shims made from a discarded Coca-Cola can would be perfectly adequate and functionally identical to those fitted by the BMW Dealer’s mechanics at exorbitant costs. John Sutherland could not see this or be convinced, so programmed was he that only the main dealer has the expertise, equipment and materials to carry out such a task.

“In the book, the narrator describes the “romantic” approach to life of his friend, John Sutherland, who chooses not to learn how to maintain his expensive new motorcycle. John simply hopes for the best with his bike, and when problems do occur he often becomes frustrated and is forced to rely on professional mechanics to repair it. In contrast, the “classical” narrator has an older motorcycle which he is usually able to diagnose and repair himself through the use of rational problem-solving skills.”

End of Part 1.

Thank you for reading.